Intelligent Burn-in Central Monitoring System

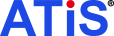

The "Intelligent Burn-in Central Monitoring System (IBCS)" is a platform-level data processing and presentation center that features centralized management, digital applications, and visual representation. It is designed to support the configuration, collection, and analysis of various burn-in equipment data. The system enables multiple interactive access points and device data sharing, as well as cluster management and remote operations.

The intelligent burn-in test control system (IBCS) consists of three main components: Burn-in Screening Equipment, Central Server, and Data Display Terminal.

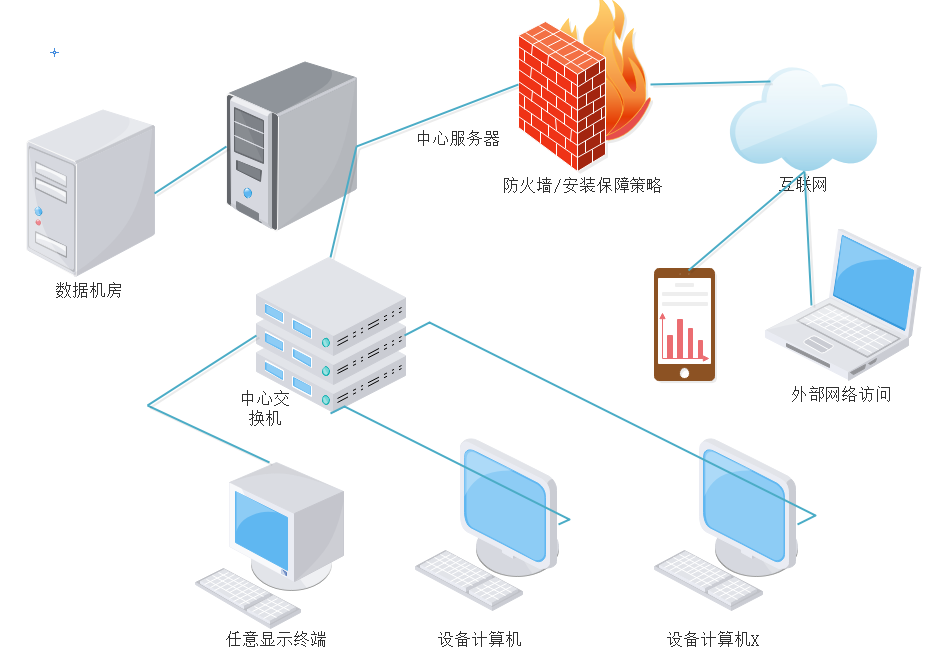

1. Burn-in Screening Equipment

The Burn-in screening equipment includes core components such as driver boards, testing chambers, power supplies, and device-side software. The device-side software provides users with a human-computer data interaction interface. Through computer software, customers can quickly edit and save burn-in parameters. They can also intuitively view the equipment's operational status and device performance from the software.

Technical Highlights:

1. Added multiple data sharing APIs, allowing rapid retrieval of device operational status, output display, and data recording through our server software/third-party data collection software.

2. Introduced a network device library API, supporting centralized device libraries.

3. Integrated interfaces for task numbers, device batch numbers, and other information, which are stored as database query-related items.

4. Implemented burn-in task distribution function, enabling automatic mismatch prompts when receiving burn-in tasks from the server and comparing them during loading operations.

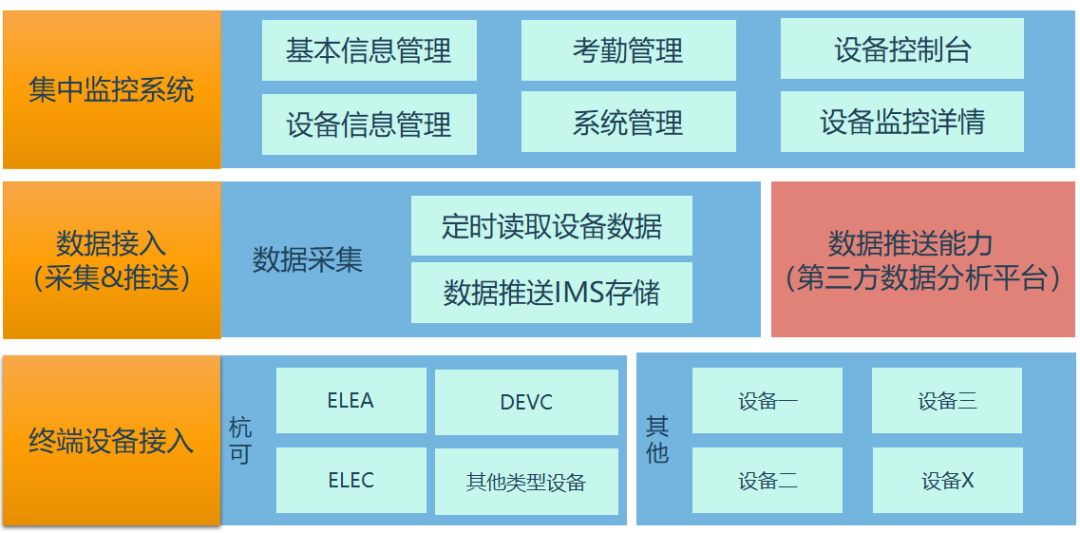

2. Central Server:

The central server acts as the core for data collection and forwarding. We provide an installation package for quick deployment of the server. Users only need to configure specific connection information to rapidly install and deploy the server-side application.

Technical Highlights:

1. Utilizes TCP/IP to collect operational statuses of devices within the local area network and packetize the data.

2. As a data center server, it forwards operational data to the requesting end for matched communication requests.

3. Acts as a data center server for the network device library, offering centralized burn-in parameter support for clients within the network, facilitating access and modification.

4. Provides personnel and task management capabilities.

5. Offers external access APIs, supporting third-party data integration.

6. Supports B/S and C/S access modes.

3. Data Display Terminal:

The data display terminal is the core of the intelligent centralized monitoring system, enabling accurate data collection, reliable data storage, efficient data analysis, and a user-friendly interface. It facilitates multiple management functions from devices to personnel, comprehensively meeting the large-scale and refined production control requirements of burn-in and screening operations.

Technical Highlights:

(1) Visual Management Interface:

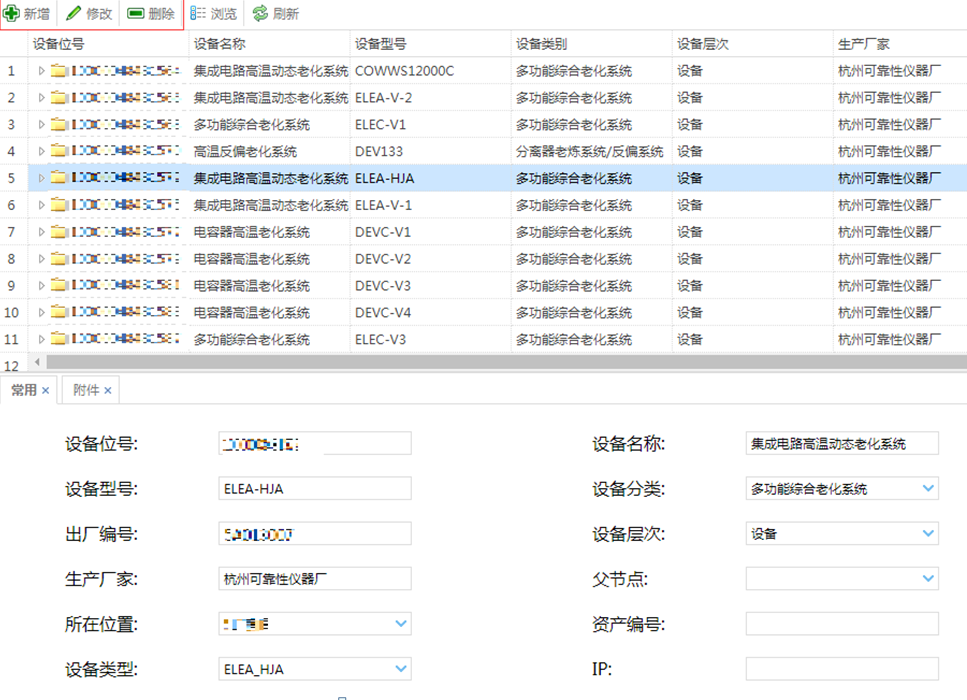

Visually displays the test chamber temperature, device operating status, and device online/offline status. Faulty devices are automatically sorted to the top for prompt troubleshooting. Supports device information management; after entering device numbers and manufacturer information, device details can be quickly accessed within the system.

(2) Remote Operation Management:

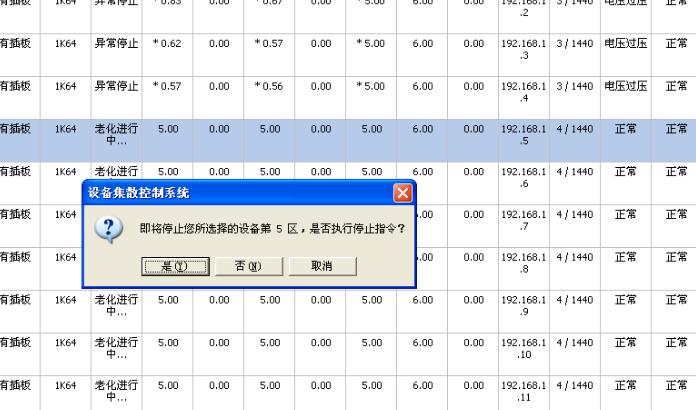

Enables remote viewing of detailed device operational status and workstation data without the need to physically visit the burn-in room. Also supports remote control, allowing remote halt of burn-in for specific sections or entire devices. Additionally, supports B/S architecture, enabling quick viewing of device cluster status through web browsers (computers/mobile devices).

(3) Device Utilization Statistics:

Supports device utilization statistics over specific time periods, allowing users to set statistical cycles and exclude interferences caused by factors like power outages or holidays. Provides a more intuitive representation of device utilization, enhancing the convenience and accuracy of production scheduling.

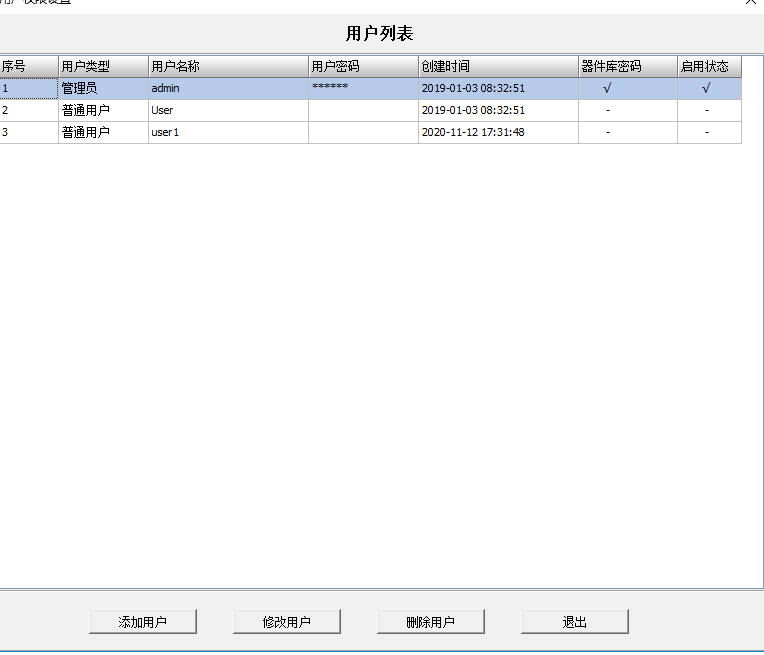

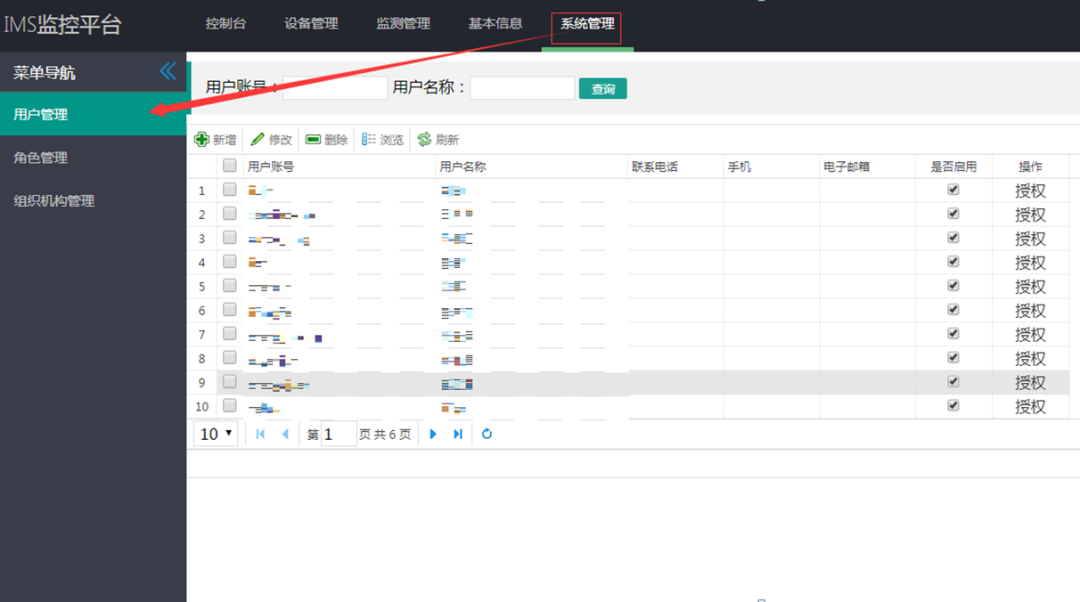

(4) User Authorization Management:

Ensures independent user accounts and passwords to prevent interference and accidental operations between clients. User privileges can be configured based on user levels. Offers shift management for staff changes, facilitating the transfer of device operational status between shifts and exporting the information to shift reports.

Additionally, supports personnel attendance management with quick export of attendance reports.

(5) Data Storage and Analysis:

Implements dual backups of burn-in data on both local (device) and cloud (server) storage. The database employs a design capable of handling millions of records and provides functionality for data deletion/transferral to address space concerns. Supports historical data tracing for burn-in, allowing rapid data filtering based on device types, burn-in task numbers, device batch numbers, burn-in times, and other information.

Advantages of IBCS Application:

Addressing the issues of ease of operation and weak data analysis capability in traditional burn-in and screening processes, the intelligent burn-in test control system (IBCS) comprehensively achieves effective optimization and improvement. It provides highly intelligent production support for multi-device and large-scale device burn-in and screening processes.

Traditional Deficiencies: | Implemented Improvements: |

1. **Isolated Equipment Operation:** Equipment operates individually and cannot be managed in a cluster. | 1. **Centralized Device Status Display Interface:** A centralized interface displays the operational status of devices, providing a comprehensive view for monitoring. |

2. **Parameter Adjustment Complexity:** Adjusting burn-in parameters requires manual intervention on each individual device, resulting in human effort wastage and low fault tolerance. | 2. **Centralized Device Library Management:** The system employs centralized device library management, allowing for parameter sharing across devices. |

3. **Limited Real-time Monitoring:** Monitoring device operation status relies on manual inspections, lacking real-time monitoring and consuming significant time and resources. | 3. **Task Allocation and Device Utilization Planning:** Efficient task allocation and utilization planning for burn-in devices. |

4. **Delayed Fault Detection:** Anomalies in devices between inspections might go unnoticed until the next inspection, leading to delayed problem identification and resolution. | 4. **Device Utilization Statistics and Analysis:** Statistical analysis of device utilization, providing insights into equipment usage efficiency. |

5. **Data Storage and Analysis Challenges:** Historical burn-in data cannot be stored for extended periods, leading to potential data loss and difficulties in data retrieval. | 5. **Burn-in Data Analysis:** Burn-in data is analyzed based on key criteria, yielding information about device failure rates and burn-in status. Customized burn-in reports are generated as per customer requirements. |

6. **Inadequate Data Analysis Capability:** The system lacks the capability to efficiently analyze historical data and generate burn-in reports based on factors such as customer, batch number, or task ID. | 6. **Precise Fault Analysis and Production Scheduling:** Accurate fault analysis leads to refined production scheduling. |

7. **Inefficient Task Allocation:** Burn-in tasks cannot be accurately allocated, leading to equipment being unused or underutilized, resulting in inefficiency and waste. | 7. **External Interface Integration:** Interfaces are available for third-party data integration, fostering innovative future applications. |

| 8. **Flexible Data Structure Design:** The system features flexible data structure design for rapid data integration upon handshake. |

| 9. **C/S and B/S Compatibility:** Compatibility with both client-server (C/S) and browser-based (B/S) modes ensures convenience and intuitiveness. |

| 10. **Local Area Network Operation:** Running on a local area network ensures data security. Additionally, the system supports firewall and routed link setups for cross-region device monitoring. |

Since its establishment in 1984, Hangke Instruments has been dedicated to the field of semiconductor device burn-in and screening. Evolving from a single discrete device burn-in equipment provider to a supplier of burn-in equipment for various devices such as integrated circuits and radio frequency devices. Over the past 36 years, we have consistently prioritized understanding customer needs and providing convenient, flexible, and highly energy-efficient high-end burn-in and screening equipment.

If you have any requirements or inquiries regarding the intelligent burn-in test control system (IBCS), please feel free to contact us. Hangke Instruments is committed to providing you with comprehensive services.